WARNING: The Flamegaurd glass bulb sprinkler is manufactured and tested to meet the rigid requirements of approving agencies. The glass bulb sprinkler is designed to be installed in accordance with recognized installation standards. Deviation from the standards or any alteration to the Flameguard glass bulb sprinkler after it leaves the factory including, but not limited to: painting, plating, coating, or modification, may render the device inoperative and would automatically nullify the approval and any guarantee made by The Flameguard Corporation.

Fire Sprinkler Systems should only be designed and installed by those component and completely familiar with automatic Sprinkler system design, installation procedures, and techniques.

Several criteria may apply to the installation and usage of each sprinkler.

Consequently, it is recommended that the sprinkler system designer review and develop a working understanding of the complete list of criteria prior to initiating the design of the sprinkler system.

Questions concerning sprinkler installation and usage criteria, which are not coverage by the following instructions, should be submitted to contact company. Include sketches and technical details as appropriate.

In some instances, the requirements of this document may concern specifications which are more stringent and which take precedence over those specified in NFPA 13, NFPA 13D, NFPA 13R, or by the authority having jurisdiction.

The spray from the sprinkler is distributed radially outward from the sprinkler deflector. Consequently, the sprinklers must be located such that there will not be any blind spaces shielded from spray by partitions, room dividers, overhangs or other parts of the dwelling structure. The number of sprinklers within each compartment (as defined by NFPA 13, 13D, or 13R) must be kept as few as possible.

Do NOT use more sprinklers than necessary to cover a particular space.

Use only the escutcheon provided with the Model FL100U, FL100P, FL200U and FL200P.

The sprinkler must be secured in position by firmly fastening the sprinkler system piping to the structure. If the sprinkler is not properly secured in position, reaction forces resulting from sprinkler operation could alter its orientation and its water distribution pattern. The sprinkler escutcheon cannot be used to hold the sprinkler in position.

- The Flameguard Glass Bulb Sprinkler is to be installed in accordance with the latest edition of Flameguard technical data, and the applicable installation standards such as the National Fire Protection Association 13(NFPA 13).

- The Flameguard Glass Bulb Sprinkler must be installed after the piping is in place to prevent mechanical damage. Before installation, be sure the sprinkler has the appropriate temperature rating. Keep sprinkler with glass bulbs contained within the protective shields during installation and testing, and any time the sprinkler is shipped or handled. Apply a small amount of pipe-joint compound to the male threads only, taking care not to allow a build-up of compound inside the orifice.

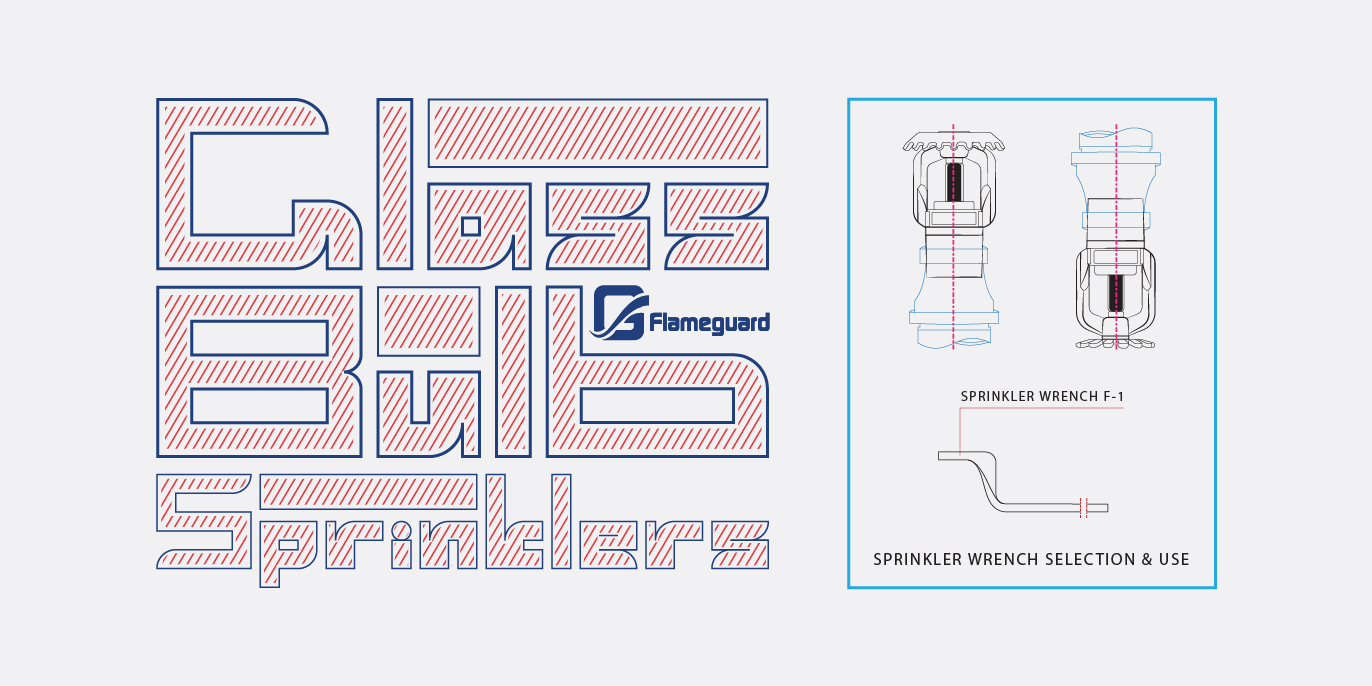

NOTE: Sprinklers with glass bulbs must be contained within the protective shields when applying pipe-joint compound or tape. Install the sprinklers on the piping using the special wrench only, while taking care not to damage the operating parts of the sprinkler.

Push on the Sprinkler Wrench, while it is being turned, to ensure that the Wrench recess stays fully engaged with the sprinkler wrench flats.

Carefully remove the Sprinkler Wrench by disengaging it from the sprinkler wrench flats, and then lowering it down over the sprinkler deflector.

- Glass bulb sprinklers must be handled with care. Never install glass bulb sprinklers that have been dropped or damaged in any way. Never install any glass bulb sprinkler if the bulb is cracked or if there is a loss of liquid from the bulb.

- A leak tight 1/2” pipe thread sprinkler joint should be obtained with a torque of 7 to 14 ft.lbs.(9.5 to 19.0 Nm). A maximum of 21 ft.lbs. (28.5 Nm) of torque is to be used to install the sprinkler. Higher levels of torque may distort the sprinkler inlet with consequent leakage or impairment of the sprinkler.

- After installation, the entire sprinkler system must be tested. The test must be conducted to comply with the installation standards.

Make sure the sprinkler has been properly tightened. If a thread leak occurs, normally the sprinkler must be removed, new pipe-joint compound or tape applied, and then reinstalled. This is due to the fact that when the joint seal is damaged, the sealing compound or tape is washed out of the joint.

Tags: Sprinklers