NOTICE: The owner is responsible for maintaining the fire-protection system and devices in proper operating condition. For minimum maintenance and inspection requirements, refer to NFPA 25 standard that describes care and maintenance of sprinkler systems. In addition, the Authority Having Jurisdiction may have additional maintenance, testing, and inspection requirements that must be followed.

- Flush type sprinkler must be inspected on a regular basis for corrosion, mechanical damage, obstructions, paint, etc. The frequency of inspections may vary due to corrosive atmospheres, water supplies, and activity around the device. Adequate heat must be maintained around the flush type sprinkler and release piping system.

- Flush type sprinkler that have been field painted, caulked, or mechanically damaged must be replaced immediately. Any Flush type sprinkler showing signs of corrosion shall be tested and/or replaced immediately as required. Flush type sprinkler that are 20 years old shall be tested and/or replaced immediately as required. Consult accepted installation standards (e.g., NFPA 25), approving agencies, and Authorities Having Jurisdiction, as different minimum testing periods may be required. Flush type sprinkler that have operated cannot be reassembled or re-used, but must be replaced. When replacing flush type sprinkler, always use new units.

- Nothing should be hung from, attached to, or otherwise obstruct the travel of heat to the flush type sprinkler from any point within its listed area of coverage. Immediately remove all obstructions or, if necessary, install additional flush type sprinkler.

- When replacing existing flush type sprinkler, the system must be removed from service. Refer to the appropriate system description and/or valve instructions. Prior to removing the system from service, notify all Authorities Having Jurisdiction. Consideration should be given to employment of a fire patrol in the effected area.

- Remove the system from service, relieving all pressure (air, nitrogen, or water) on the sprinkler line piping.

- Drain water from hydraulic sprinkler lines and remove any moisture present in pneumatic sprinkler lines.

- Using the special wrench, remove the old flush type sprinkle, and install the new unit. Care must be taken to ensure that the replacement unit has the proper temperature rating. A fully stocked sprinkler equipment cabinet should be provided for this purpose.

- Place the system back in service and secure all valves. Check for and repair all leaks.

- Sprinkler systems that have been subject to fire must be returned to service as soon as possible. The entire system must be inspected for damage and repaired or replaced as necessary. Sprinklers that

have been exposed to corrosive products of combustion or high ambient temperatures, but have not operated, should be replaced. Refer to the Authority Having Jurisdiction for minimum replacement requirements.

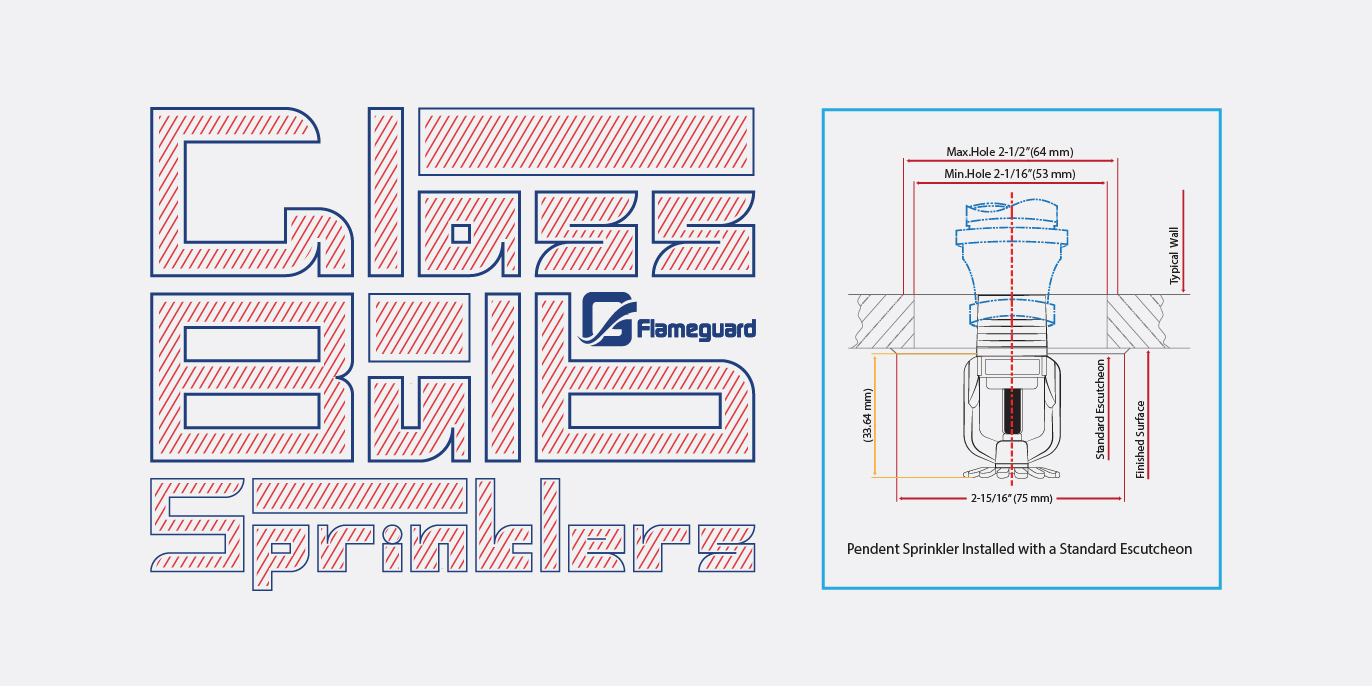

- Absence of an escutcheon, which is used to cover a clearance hole, may delay the time to sprinkler operation in a fire situation.

- Before closing a fire protection system control valve for maintenance work on the fire protection system, which it controls, permission to shut down the affected fire protection system must be obtained from the proper authorities and all personnel who may be affected by this action must be notified.

- It is recommended that automatic sprinkler systems be inspected quarterly by a qualified Inspec-tion Service.